Double eleven, Christmas season is approaching the improvement of textile market

Since the beginning of this year, under the influence of various unfavorable factors such as the Sino-US trade dispute, weak external demand, continuous increase in various production costs and management costs, the market situation of the textile printing and dyeing industry is grim, as can be seen from this price increase notice, The increase in dyeing fees is really helpless!

The time has come to mid-to-late October, and the dye factory has also issued price increase notices. Although it is only an individual phenomenon, there is hope for price increases! Is the market slowly improving? Is there any hope for "Silver Ten"?

The delivery time of the dyeing factory has been extended, and some dyeing factories have burst positions!

It is said that the market of the textile market is good or not, depending on whether the printing and dyeing factory has a lot of work. Although this statement is somewhat absolute, it does reflect the changes in the textile market from the printing and dyeing side.

Recently, the number of dyeing plants in Jiangsu and Zhejiang areas has shown an upward trend, and the operating rate of dyeing tanks has risen to about 100%. Affected by the double eleventh stocking and pre-sale, the market orders flooded into printing and dyeing factories, so the printing and dyeing factories that made the market orders started to get busy. The manager of a dyeing plant in Shengze area who has been making market orders all the year round said that the printing and dyeing market entered a small peak season in October, mainly due to the increase in market products, so the overall order volume increased. There are even cases where some dyeing factories have burst their warehouses.

Overall, the average delivery time of most dyeing factories is currently 10-15 days, which is longer than the previous period. The market goods have increased a lot, and the order goods have also gradually increased. In terms of products, the number of winter fabric dyeings such as Nylon, Nylon, Polyester, Suede, and suede began to increase; the number of stretch series grey fabrics is still rising; other varieties are more messy, mainly autumn and winter fabrics.

Generally speaking, for the upcoming "Double Eleven" and Christmas, the market will stock up 1-2 months in advance, which is currently in this stocking period. So, are there more orders from traders?

Traders: Market orders and orders have begun to "risk"!

It is customary to place a large number of market orders before the double eleven every year. At this time, e-commerce has a large demand for clothing. Therefore, garment factories will place orders in large quantities to make clothing, which will lead to a hot market. An integrated industry and trade company that makes market orders in Shengze said: "The recent list is a little bit more than in September. Conventional fabrics have started to loosen, and the grey cloth inventory in our factory has decreased from last month."

In addition to market goods, orders have gradually increased recently. In terms of foreign trade, Sino-US relations in September this year have eased, which has boosted the confidence of the textile market to a certain extent. According to relevant data, orders for textile and apparel foreign trade increased in September. Although many textile bosses this year worry that the Sino-US trade will be divided, the order may be transferred or cancelled. However, according to some foreign trade companies, their orders are still relatively stable.

A foreign trade company responded: "At present, the number of company orders is indeed increasing. This time the Sino-US trade war has been sawing for too long. Some US apparel companies have almost consumed the stocks. The demand for Christmas can still be released. It should be issued. Orders will still be placed." An integrated industry and trade enterprise in Wuxi, which mainly sells polyester taffeta, oxford cloth, and nylon spinning, also revealed to the editor: "Our orders have been okay. Compared with September, orders There has been an increase. It is mainly based on Oxford cloth and is mainly sold to European countries."

Since October, due to the impact of lower temperatures, the cold-proof clothing fabrics have started to improve, and the demand for fabrics by brand manufacturers and clothing factories will also improve. Seasonal demand still exists. An enterprise in Wujiang said: "At present, orders can be made around December, mainly T400, imitation memory, cool silk cotton, etc. Sold to Keqiao, Guangzhou and other regions, this year tends to stretch fabrics, although not very hot Products sold, but our orders are still relatively stable."

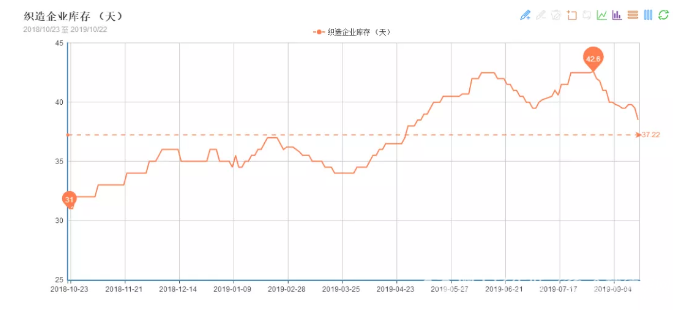

On the whole, although most traders have indicated that orders have improved, the textile market is still facing overcapacity. The two-level market differentiation is serious, and hot-selling fabrics are missing. In order to withdraw funds, some conventional grey cloth manufacturers still have the phenomenon of selling goods at low prices. Judging from the data monitored by China Silk Capital, the grey cloth inventory in Shengze area is about 39 days, which is lower than the previous period, but the overall is still at a high level.

Editor

With the approaching of the Double Eleven and the Christmas season, market orders and orders have improved to a certain extent. However, it seems that there are still some difficulties in solving the problem of overcapacity in the market.

This year, whether it is a weaving enterprise, a trader or a dyeing factory, the days are not so good. It may be the most difficult year. Not only are the orders missing, the inventory is high, but the profit is minimal! Regardless of whether the bosses can receive a big order, you are all good! Doing business is not easy, and it is cherished!

- Prev没有了!

- Next没有了!